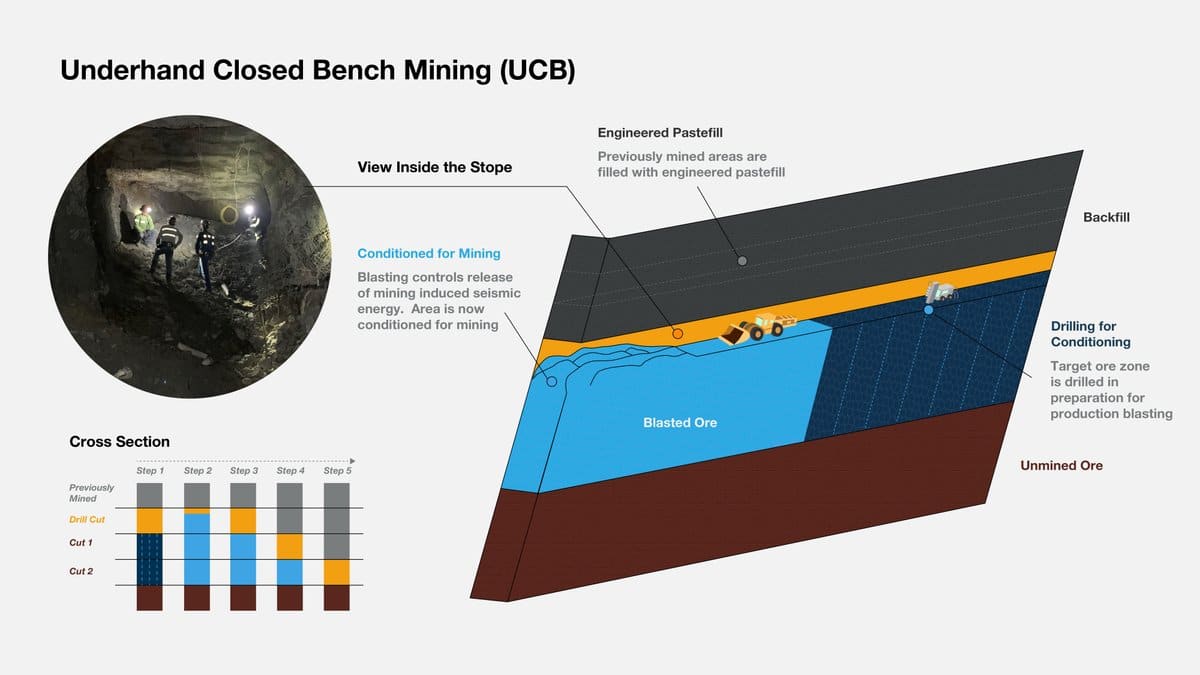

Innovation

Hecla embraces advanced technologies and practices to enhance social license, improve safety, enhance productivity, improve environmental stewardship, reduce environmental impact, and improve efficiency. We cultivate a culture of respect, trust, and continuous improvement to drive shareholder value and operational success. Our company pioneers innovative approaches to business, striving for excellence in every aspect of operations.